Miyako Roller Industry

Miyako Roller IndustrySaitama prefecture, 340-0027 JAPAN

Miyako Roller Industry

Miyako Roller Industry

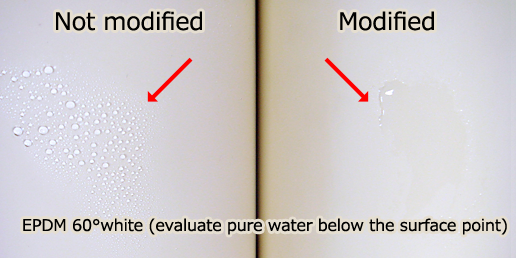

Reduce wrinkles occurring on the nip roll and feed roller and damages on the base material and improve the peeling performance by lowering the surface energy of a rubber roll.

The durability of rubber can be decreased by forcibly deteriorating rubber (surface modification by chlorine) in the conventional surface modification method for rubber rolls. We have established non-chlorine modification of NP-1 to modify the surface of a rubber roll, which improves the durability of rubber and is friendly to the environment.

| Not modified | Modified | |

|---|---|---|

| Hardness | 58-62° | 58-62° |

| Surface Roughness | Ra:0.390 μm | Ra:0.332 μm |

| Friction Coefficient | 1.6 | 0.31 |

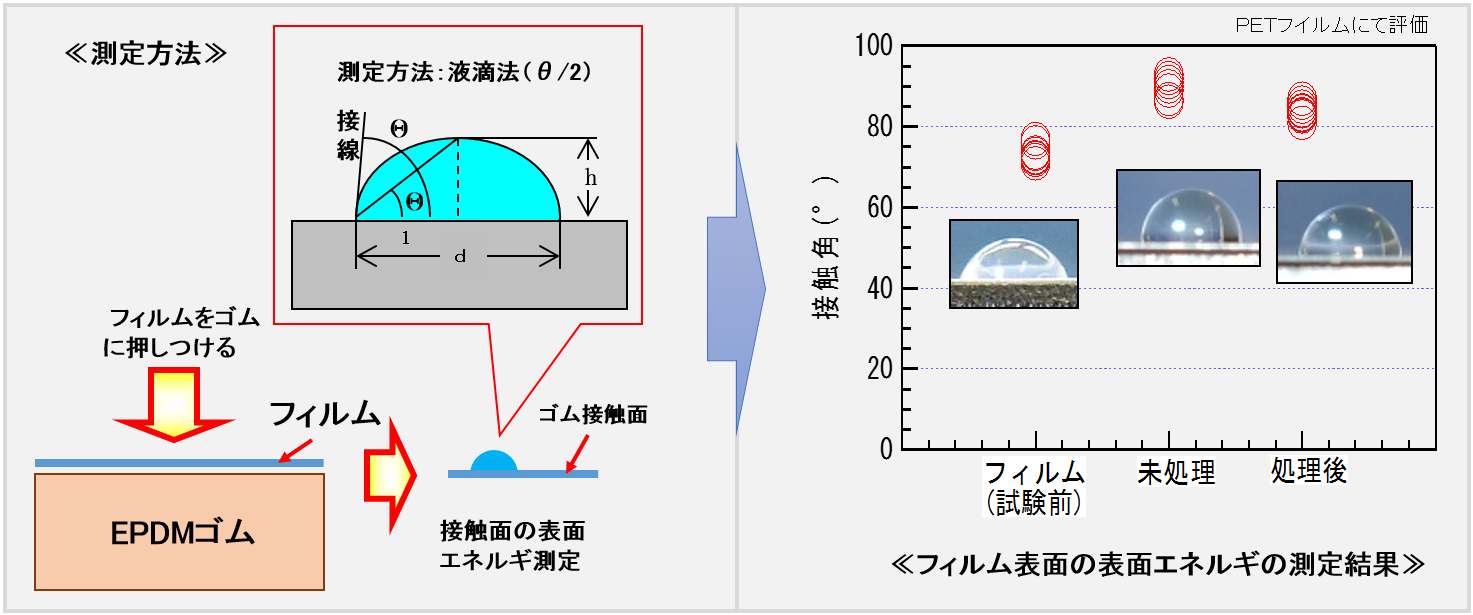

To examine effects of the substance eluted from EPDM rubber on the opponent material (film), measure the surface energy of a film by contacting the film onto the rubber surface before and after modification.