Miyako Roller Industry

Miyako Roller IndustrySaitama prefecture, 340-0027 JAPAN

Miyako Roller Industry

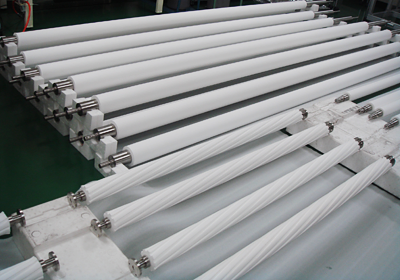

Miyako Roller IndustryThere are two types of sponges available, namely special polyurethane resin and olefin-based resin. An ultra-micro open-cell structure is realized by extrusion molding using a liquid sintering method, which results in excellent water absorption. It is a high-performance water draining roll optimal for electronic parts such as PCBs, films, and glass substrates requiring high quality and high precision, and other industries.

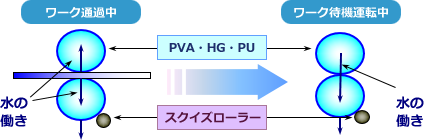

Water on the surface of boards or substrates is absorbed immediately due to the open-cell structure with ultra-micro cells of 10-30μm in diameter.

In addition, the outer surface of a roller is grinded.

Drying temperature can be lowered, and line operation can be expedited due to excellent draining and squeezing effects.

In addition, this sponge has no surface film as it is abrasion-resistant, which is an excellent feature of urethane-base materials, and it is devised to prevent lint or dust from re-attaching. Compared to other squeezing rollers, yield can be gained several times more.

It provides excellent flexibility and a water-absorbing feature, so it never hardens even in a dry condition.

For that reason, cylindricity and circularity can be maintained without supplying water.

We can ship cleaned sponges as well.

Performance of a Water-Absorbing Roll = Water-Absorbing Capability + Drainage Capability