Miyako Roller Industry

Miyako Roller IndustrySaitama prefecture, 340-0027 JAPAN

Miyako Roller Industry

Miyako Roller Industry| Measurement Item/Intended Use | Equipment Name | Manufacturer |

|---|---|---|

| External Diameter | Laser Measuring Instrument | Mitutoyo |

| Tooth Thickness Micrometer | Mitutoyo | |

| Digital Vernier Caliper | Mitutoyo | |

| Laser Displacement Sensor | KEYENCE | |

| Roll External Diameter Laser Measuring Instrument developed by our technology | Miyako Roller Industry | |

| Rubber Hardness | JIS (Japanese Industrial Standards) Rubber Hardness Tester (Classification A, C, D) | TECLOCK |

| Surface Roughness of External Diameter | High-Performance Image Processing System (2 units) | OMRON |

| Surftest SJ-210 Series | Mitutoyo | |

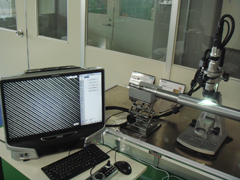

| Surface Image | Digital Microscope (VHX6000) | KEYENCE |

| Surface Length | Laser Measuring Instrument | KEYENCE |

| Pressure | Roll Crimping Tester (Effective width: 1650 mm) designed by our company | Miyako Roller Industry |

| Pressure-Sensitive Sheet | FUJIFILM | |

| Pressure Distribution | Pressure Distribution Measuring System | Nitta |

| Cleaning | Ultrasonic Cleaner for 3M Roll | Otari |

| Ultrasonic Cleaner for 1M Roll | Otari | |

| Nano Bubble Cleaner for 1M Roll | Otari | |

| Wear Coefficient | Wear Meter | Miyako Roller Industry |

| Viscosity | Viscometer | ATAGO |

| Surface Pressure | Measuring System for Surface Pressure Distribution | Nitta |

| Coating Thickness | Coating Thickness Measurement Sensor | OMRON |

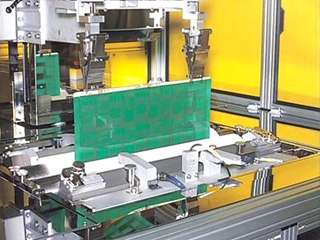

| Coating Machine | Photosensitizer Coating Machine for Double-sided PCBs, uniquely developed by our company | Miyako Roller Industry |

| Coating Machine (800 mm, 600 mm, 400 mm), uniquely designed by our company | Miyako Roller Industry | |

| Surface Resistivity | Resistivity Measuring System for the surface of the conductive rubber | Mitsubishi Chemical |

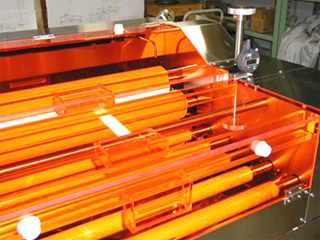

| Drying Equipment | 0.5 m×0.5 m×1.5 m | FUJI KAGAKU KIKAI |

| 2 m×1 m×1 m | TONETSU | |

| 4 m×1 m×1 m | TONETSU | |

| 1 m×1 m×1.5 m | Kusumoto Chemicals | |

| UV Equipment | Portable | SEN LIGHTS |

| Water Contact Angle | Simage Entry 5 | Excimer |

| Roll Measurement | Our Processing Equipment | |

|---|---|---|

Roll runout and cylindricity are measured with a laser displacement sensor. Roll runout and cylindricity are measured with a laser displacement sensor. |

The surface is examined with a CCD image sensor. The surface is examined with a CCD image sensor. |

Maximum roll processing dimension

|

We have our patented coating machine installed in our lab where the most up-to-date equipment is installed to develop, evaluate, and establish quality assurance of coating liquid. We are more than happy to work hard to help customers research and develop their products.

Coating Machine: Roll Evaluation Equipment 1

Coating Machine: Roll Evaluation Equipment 1 Coating Machine: Roll Evaluation Equipment 2

Coating Machine: Roll Evaluation Equipment 2 Coating Machine: Roll Evaluation Equipment 3

Coating Machine: Roll Evaluation Equipment 3 Surface Pressure Measuring and Test Equipment

Surface Pressure Measuring and Test Equipment Feed a glass substrate

Feed a glass substrate Measure the surface pressure by contacting a roll

Measure the surface pressure by contacting a roll