Miyako Roller Industry

Miyako Roller IndustrySaitama prefecture, 340-0027 JAPAN

Miyako Roller Industry

Miyako Roller Industry

| Company Name | Miyako Roller Industry Co., Ltd. |

|---|---|

| Established | October 1, 1973 (Launched on April 1, 1953) |

| Capital | 70 million yen |

| President | Seiji Machida |

| Headquarters | 112-2 Ryoshindennishi town, Soka city, Saitama prefecture, 340-0027 JAPAN |

| Fukushima Satellite Plant | 375-3 Sakuraoka, Kagamiishi town, Iwase county, Fukushima prefecture, 969-0403 JAPAN E-mail: miyako-rollerf@air.ocn.ne.jp |

| Services | - Fabrication, sales, and coating of various rolls for printing and industrial use - Manufacturing and sales of precision coating machine - Sales of eco-friendly coating materials |

| Number of Employees | 20 (including one researcher) |

| Banks | - Mizuho Bank - Saitama Resona Bank |

| Customers | - Mitsubishi Chemical Group - Fujifilm Group - Sumitomo Chemical Group - Dai Nippon Printing Group - Toppan Printing Group and more |

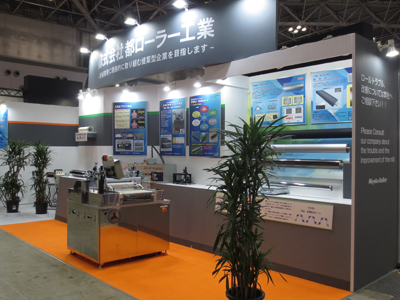

SPS IPC Drives 2015, in Germany

SPS IPC Drives 2015, in Germany Glasstech Asia 2017, in Singapore

Glasstech Asia 2017, in Singapore Convertech JAPAN 2017

Convertech JAPAN 2017| April 1953 | Established as a limited company. Started grinding of rubber rollers for offset printing |

|---|---|

| October 2001 | Certified as one of the Support Agencies for Business Innovation |

| November 2003 | Built a mass-production plant in Kagamiishi town, Fukushima, and started operation (Fukushima Satellite Plant) |

| November 2005 | Designated as a "Sai's Country Plant" by Saitama prefecture |

| June 2006 | Raised capital to 70 million yen |

| June 2008 | Selected as one of the 300 of Japan's Vibrant Monodzukuri (Manufacturing) SMEs, 2008" by Minister of Economy, Trade and Industry |

| December 2008 | Approved a management innovation plan by Saitama prefecture |

| April 2009 | Made an agreement on technology development with Professor Takeuchi at Nippon Institute of Technology (Research and Development Center for Advanced Materials and Technology) |

| August 2009 | Moved headquarters to Soka city, Saitama prefecture |

| August 2009 | Certified regarding "Act for the Sophistication of Basic Manufacturing Technology of Small and Medium Enterprises" by the Kanto Bureau of Economy, Trade and Industry |

| August 2009 | Granted for supporting product development by small and medium manufacturing companies, by the Bureau of Economy, Trade and Industry |

| January 2010 | The DLC coating roll was certified as "Kawaguchi i-mono" brand products by Kawaguchi Chamber of Commerce and Industry. |

| December 2010 | Certified regarding micro 3D coating technology development for fuel cell separators by DLC coating at a room temperature by the Kanto Bureau of Economy, Trade and Industry |

| June 2012 | Received a certificate of a support product from Tokyo Metropolitan Small and Medium Enterprise Support Center |

| May 2013 | Received Management Innovation Award from Honoring System Review Committee for members of Kawaguchi Chamber of Commerce and Industry |

| January 2015 | Registered in the environmental technology data base (nano technology industrial coating) by UNIDO (United Nations industrial Development Organization) |

| October 2015 | Received a certificate of export support for coating machine by JETRO (Japan External Trade Organization) |

| February 2016 | Management Innovation Plan was approved by Saitame prefecture. |

| August 2016 | Granted for supporting product development by small and medium manufacturing companies, by the Bureau of Economy, Trade and Industry |

| November 2016 | Certified regarding a management capability improvement plan by the Kanto Bureau of Economy, Trade and Industry |

| December 2016 | The multi-functional precision coating machine was certified as "Kawaguchi i-mono" brand products by Kawaguchi Chamber of Commerce and Industry. |

| May 2017 | Granted for 2017 Saitama New Technology & Commercialization Development |

Designated as a "Sai's Country Plant" by Saitama pref

Designated as a "Sai's Country Plant" by Saitama pref Certified as "Kawaguchi i-mono" brand products

Certified as "Kawaguchi i-mono" brand products Certificate of Management Innovation Plan

Certificate of Management Innovation Plan Management Innovation Award

Management Innovation Award 300 of Japan’s Vibrant Monodzukuri (Manufacturing) SMEs, 2008

300 of Japan’s Vibrant Monodzukuri (Manufacturing) SMEs, 2008

112-2 Ryoshindennishi town, Soka city, Saitama prefecture, 340-0027

JAPAN

By train:Tobu Skytree Line (from Tokyo Metro Hibiya Line) Get off at Takenotsuka Station and take West Exit.

By car:It takes approx. 7 minutes from West Exit.

By bus:Take a bus (displayed as "竹04・05") heading for West Exit of Soka Station at No.2 bus terminal, or take a bus (displayed as "竹06・09) heading for West Exit of Takenotsuka Station via Nissato. Get off at Shitamachi. It takes approx. 6-min walk.

375-3 Sakuraoka, Kagamiishi town, Iwase county, Fukushima prefecture, 969-0403

JAPAN

E-mail: miyako-rollerf@air.ocn.ne.jp