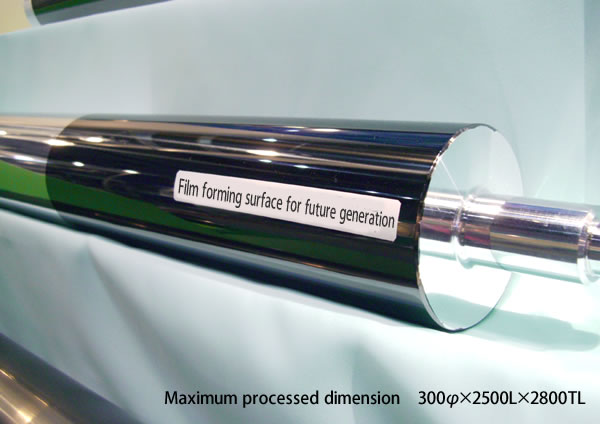

Environment-Responsive ordinary temperature DLC coating Gide Rolls for Conveying

Developed with Subsidy to Small and Medium Manufacturing Enterprises for Product Development etc.

Ordinary Temperature DLC Processed Materials

- Surface of Rubber Roll (NBR Rubber)

- Surface of CFRP Roll

- Surface of Aluminum

- Surface of Plastic Resin

- Surface of Hard Chrome Plating

- Surface of Engraved Roll

- Ceramic Surface

Features (Optional functions available according to intended use)

- Low friction coefficient : 0.2 and under (crease free, preventing damage to the couterpart material)

- High hardness and abrasion resistance : DLC (around 1500 HV) is harder than the Hard Cr plating (around 900HV max),

scratch-resistance, substitute for fluorine resin coating roll (harder than fluorine resin coating) - Corrosiveness : Improved abrasion resistance / corrosiveness by DLC coating

- Super-hydrophilicity : Contact angle with water 20-30°possible (controllable film thickness of solution coating)

- Water repellency : Contact angle with water 90-100°possible (correspondent to the doctor blade)

- Electrical resistance value : 106 – 1010 Ω (anti-adhesion to dust)

- Friction reduction of CFRP : Prevention of abrasion dust

- Antibacterial effect provided

- Stain resistant (fluorinated DLC)

Example

Conveying rolls for film manufacturing, printing industry, and paper printing industry, etc.